The main devices are as follows:

1. Adjustable feeding device: 1 set with position display.

2. Guide leveling device: 1 set.

| Lead Roller Material and Quantity | The guide roller is a rubber-coated roller |

| 15-roll leveling, 7-up and 8-down | |

| Leveling roller material | 45#, hard chrome plating on the surface, heat treatment HRC46-52; |

| Motor power | 2.2KW |

3. Hydraulic shearing device:1 set

| Hydraulic station configuration | share hydraulic station with shear bending |

| Uncoiler hydraulic system pressure | the last cut the head of the coil and the tail of each batch |

| No blanking shears, tool material | Cr12MoV, heat treatment hardness HRC58-62 |

4. Adjustable hydraulic punching device:2 sets

| Punch and tail hole mechanism | 1 set for each left and right, can be called on both sides, and can be switched through the touch screen |

| Box and punching station | placed on a mobile bracket to achieve synchronous adjustment (manual fine-tuning) |

| Punching material | Cr12MoV |

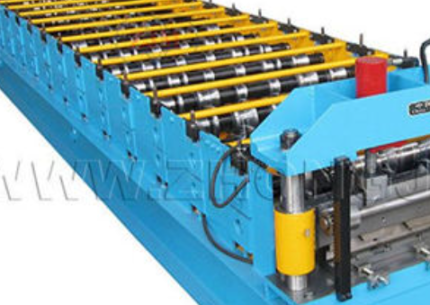

5. Roll forming machine:1 set

| Width adjustment method | plate width is adjusted in the middle, controlled by servo motor |

| Working height | 900mm |

| Guide | Configure secondary guide |

| Width adjustment | On the basis of batch production, plates of different sizes are added to achieve alternate production, and the frame is processed as a whole after welding to ensure adjustment accuracy |

| Adjustment mechanism | high-precision standard linear guide |

| Transmission mode | gear sprocket transmission (all upper shafts have gears) |

| Number of molding passes | 10 moldings |

| Roller material | 45#, the outer surface of the roller is treated with high frequency HRC56-62, CNC machining, the surface of the roller is polished |

| Molding speed | about 12.5m*/min |

6. Hydroforming shearing & bending mechanism:1 set

| Shearing method | stop shearing, blanking shearing |

| Tolerance range | After cutting, the end are automatically bent upward, and the bending angle of the end and end is 90 degrees tolerance ± 1 degree Shear length tolerance and adjacent notch tolerance is ≤0.5mm |

| Oil pump power | 4KW |

| Shearing pressure | maximum 12Mpa |

| Shear material | Cr12MoV |

| Heat treatment | HRC58-62 |

| Shearing tool | 1 set |

7. PLC console:1 set

| Function | Automatically control cutting length and cutting quantity |

| Forming length tolerance | ≤0.5mm |

| Forming length tolerance | ≤0.2mm |

| Control voltage | 24V |

| Main components of electrical appliances | PLC (Siemens), touch screen (Siemens), encoder (Omron), dual photoelectric detection, etc. |

Reviews

There are no reviews yet.