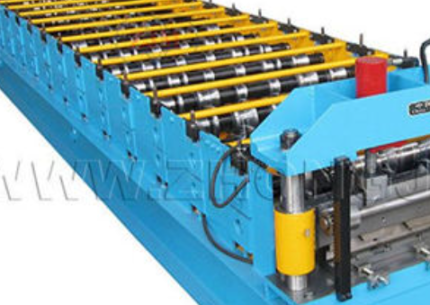

Main feature:This unit is composed of 3T manual feeding device, leveling device, transmission device, forming roller table and host (including guiding platform), cutting device after forming, hydraulic system, electric control system, finished product supporting device, etc. Loading and uncoiling (put the steel coil into the inner support type opening frame and tighten it tightly) The two-roll clamp feeds the plate into the calibration and is correctly introduced into the leveling, roll forming, cutting after forming, and the finished product is supported and discharged.

Technical parameter:

|

parameter |

unit |

|

structure |

wall panel |

|

raw materials |

Galvanized steel |

|

Feed width approx. |

1000 |

|

effective width |

760/900 |

|

thickness |

0.4-0.6 |

|

Yield Strength |

350 |

|

line speed |

10 |

|

Number of forming groups |

14 |

|

Spindle material |

45# high quality steel, quenched |

|

Spindle diameter |

75 |

|

Main motor power |

10 |

|

Hydraulic station power |

5.5 |

|

Cutting Method |

Hydraulic shear, cut off after forming |

Reviews

There are no reviews yet.