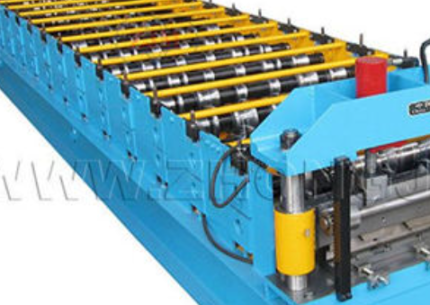

The main feature: 1. Raw material specification: 1.2~1.5mm galvanized steel strip; 2. Uncoiling method: 3 tons manual uncoiling (coil inner diameter: 508mm); 3. Main motor power: 15KW; 4. Forming speed: 10m/min (including cutting time); 5. Number of rolls: 26 horizontal rolls and a series of vertical rolls; 6. Spindle diameter: 75mm; 7. Machine structure: archway type, single row 1.5 inch chain; 8. Roll material: high-quality bearing steel GCr15, quenched at 58-62 degrees, and the surface is finished after direct quenching without any other treatment. 9. Control system: Siemens PLC control system is adopted; 10. The frame is made of 450 channel steel, positioned on both sides; 11. Cutting method: adopt the method of tracking and sawing after forming; 12. Cut off motor power: 3KW; 13. Saw blade shape: cut by circular saw; 14. Cutting accuracy: ±2mm 15. The shortest cutting length: 2.5m (when the production speed is 5m/min) 16. Voltage requirements: 380V; 17. The length X width of the main machine: about 13.5 meters (cut off with the saw) X2 meters (including the external motor). 18. Beam-type unit replacement method: The boss part is replaced by hoisting, and the bracket is installed after lifting. 19. Time for replacement and commissioning of beam-type units: 1-2 hours (after workers are normally trained and qualified for independent work). Technical Data:

|

parameter |

unit |

|

Raw material specifications |

1.2~1.5mm galvanized steel strip |

|

Uncoiling method |

3 tons of manual uncoiler (coil inner diameter: 508mm) |

|

Main motor power |

15KW |

|

Forming speed |

10m/min (including cut-off time) |

|

Number of rolls |

26 horizontal rollers and a series of vertical rollers |

|

Spindle diameter |

75mm |

Reviews

There are no reviews yet.