-

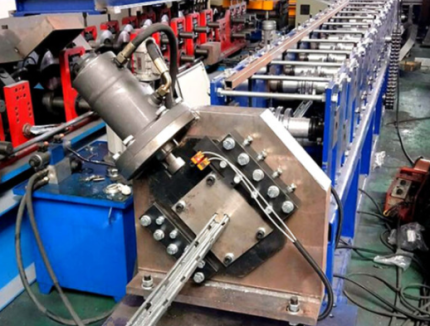

Our cable tray roll forming machine is capable of making different sizes of cable trays through automatic adjust and replacing punching mold. The cable trays produced by this roll forming production line are extensively used in petroleum, chemical, electric power, light industry, television, and telecommunications. The utility model has the advantages of light weight, large load, beautiful appearance, simple structure and convenient installation, and the utility model is suitable for the installation of the power cable and the laying of the control cable.

-

With full and special experience, we can customize cable tray forming machines or cable roll forming production lines according to customers’ profile drawing and specifications. Other high quality equipment, including metal roll forming machine are also provided as you require.

-

Working flow: Uncoiler—Leveling—Feeding—Punching&Cutting—Roll forming—Output table

|

Suitable raw material |

Galvanized steel sheet; thickness:0.8-2mm |

|

Forming speed |

About 10-20m/min. |

|

Production speed |

About 6-8m/min. |

|

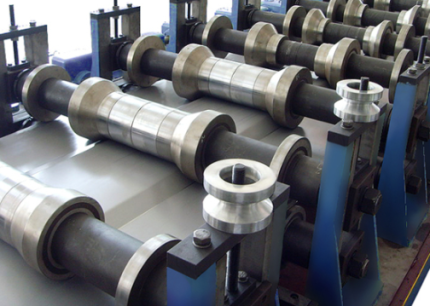

Material of forming rollers |

Gcr15, quenched treatment, |

|

Material of cutter, |

Cr12Mov HRC58-60 |

|

Material of shaft |

High quality 45# steel with heat treatment. |

|

Type of cutting |

After roll-formed and length-set cutting |

|

Total motor power |

about 50Kw |

|

Control system |

Mitsubishi /Siemens PLC |

Reviews

There are no reviews yet.