-

The purlins are now commonly used in the construction industry, with different shapes and sizes, the most commonly used are C purlin and Z purlin. Dingbo’s purlin forming machine can produce both C and Z products on the same machine. It only takes 40 minutes to change between C and Z. In addition, the purlin machine can produce sizes between 100 and 300, easy to adjust, in just ten minutes.

-

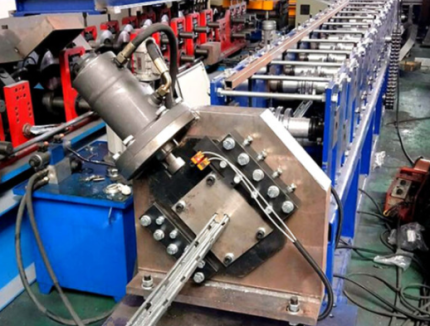

What’s important is that our purlins can be designed with a punching device and a punched hole in the punch that can be tightened during installation. The operation is simple, the PLC control works automatically, and the machine ensures high-precision operation with a tolerance of ±1mm.

-

Working Flow: Hydraulic Decoiler — Guiding device –Hydraulic Punching– Roll-forming — Cutting device — Run out table

- The specification of the rolling production (mm): 80-300×L (see appendix 1)

- The speed of the roll-in: 12-15M/min

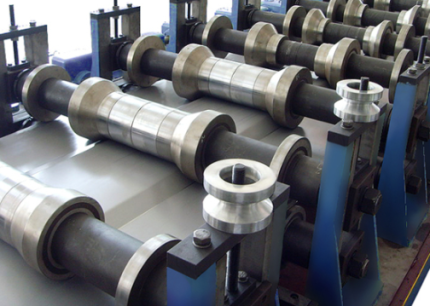

- The number of the roller: 18

- The material of the roller: use the excellent hammered steel Cr15 to be quenched as a whole, then to process by numerical control.

- The material of the principal axis: use the excellent steel No.45 to process.

- The power of the principal electric motor: 18.5kw

- Hydrodynamic station cut: 7.5kW

- Drive-by-wire system: The whole machine uses the PLC industrial computer to control by frequency conversion.

- The size of the shape equipment: 10.3×1.5×1.2m

- The gross weight of the equipment: 12.5T

Main Components

-

No.

Name

Qty

1

Hydraulic decoiler

1

2

Guiding device

1

3

Hydraulic punching

1

4

Main roll forming machine

1

5

PLC Control box

1

6

Hydraulic station

1

7

Run out table

2

Reviews

There are no reviews yet.