-

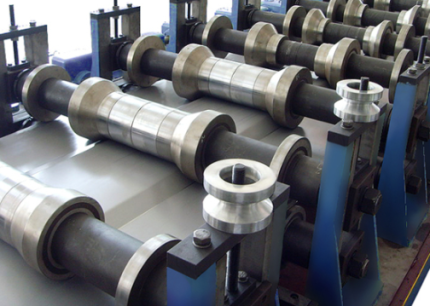

Strut Channel Roll Forming Machine production line is to produce the strut channel as solar mounting frame. Forming machine is combined and adjustable, the change size through adjust distance of rollers to complete.

-

Technological process: Uncoiler—Material Storage—Leveling—Material storage—Servo feeding—Punching—Material storage—Roll forming—Cutting—Output table

|

|

Items |

Specifications |

|

Material of coil |

Material Width |

As per sketch |

|

Material Thickness |

1.5-3mm |

|

|

Manual Uncoiler |

5 tons |

|

|

Leveling |

5rollers |

2rollers up, |

|

Servo feeding |

Model |

NC300 |

|

Motor |

2.2kw |

|

|

Press machine |

Model |

80T |

|

Mould material |

Cr12Mov,quenching HRC 58-62° |

|

|

Forming system |

Rolling Speed |

6-8m/min |

|

Roller Stations |

20stations |

|

|

Roller Material |

Gcr15, quenching, HRC 58-62 |

|

|

Shaft diameter |

76mm |

|

|

Shaft Material |

45#steel | |

|

Main Motor Power |

22kw |

|

|

Frame structure |

Memory archway |

|

|

Transmission |

Gearbox |

|

|

Correction |

Turkey head | |

|

Cutting system |

Hydraulic Power |

3kw |

|

Cutting blade |

Cr12Mov,quenching HRC 58-62 |

|

|

Tolerance |

+-1.5mm |

|

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase |

|

PLC Control System |

SIEMENS/Panasonic |

|

No. |

Name |

Qty |

|

1 |

Manual Uncoiler |

1 |

|

2 |

Leveling |

1 |

|

3 |

Servo Feeding |

1 |

|

4 |

Press machine |

1 |

|

5 |

Roll Forming Machine |

1 |

|

6 |

Cutting |

1 |

|

7 |

PLC Control Box |

1 |

|

8 |

Hydraulic Pump Station |

1 |

|

9 |

Output Table |

2 |

Reviews

There are no reviews yet.