-

Rack shelf roll forming machine produce rack shelf for super market, for warehouse, for the small market, for the racks, the cooling rooms.

-

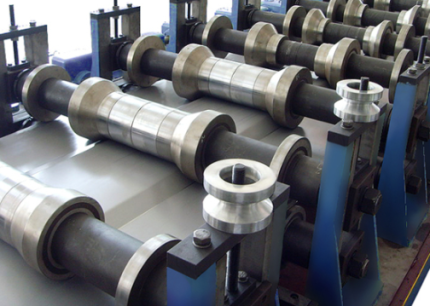

With the production advantage of the shelving & storage racks Roll Forming Machine, an extensive catalogue of shelving, light duty shelving, warehouse shelving and racking for the home and office are developed rapidly.

-

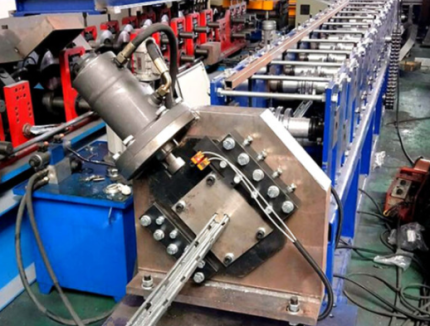

Working flow: Decoiling → Feeding → Flying hole-punching → Roll forming →Hydraulic cutting-off→Run-out table

-

1. Materials to form: According to the customers’ requirement Used for 200mm-600mm (one-sided slide-able, adjustable by electric)

2. Forming steps: About 18 steps

3. Material of rollers:GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers: >¢150

4. Material of main shaft : 45# high quality steel (diameter>¢50)

5. Chains’ material: 45# steel, high frequency quenching, circular pitch: 38.1; number of teeth: 13

6. Cutting: Hydraulic cutting; quenching HRC58-62

7. Electronic control: PLC control

8. Dimension of machine: 12000mmX2000mmX900mm

10. Drive system: Chain drive, 7.5KW main motor power, working speed: 3-15m/min

11. Welding structure: material of fixed beam and walking beam: hot-rolled steel, the base and rack are be gantry planer processing after welded, work platform is not allowed stress deformation; main machine table-board’s plainness <2mm/1000mm

12. Parts: Slide: imported from Japan; bearing: Zhonghang Brand of Harbin

13. Punching: Punching the holes at the press machine before forming the shapes

14. Bending: Bending after the hydraulic cutting

- Hydraulic De-coiler——————————1set

- Forming machine——————————–1set

- Cutting device ———————————–1set

- Punching machine——————————-1set

- PLC control box ———————————1set

- Hydraulic pump station————————-1set

- Hydraulic punching device———————1set

- Bending———————————————1set

- Production support table———————–1set

Reviews

There are no reviews yet.