-

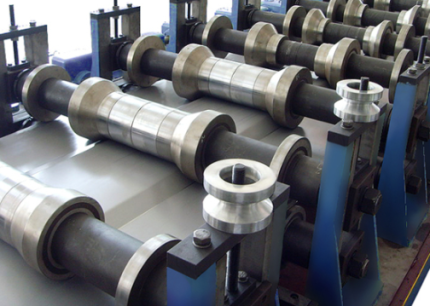

Door frame roll forming machine consists of hydraulic uncoiler, leveler, punching device, roll forming unit, shearing, run-out table, hydraulic station and electric control cabinet. The hydraulic station of the door frame roll forming machine adopts accumulator and PLC controller to generate a fast punching and shearing speed. When this cold roll forming line runs automatically, the maximum speed can reach up to 20 m/min with a stable and reliable performance.

-

Equipped with various hydraulic punching and notching unit, the machine can cut/ punch all the necessary holes/ notches online. After that, one piece of final product can be easily bended to a complete door or window frame, no need any further processing.

-

Uncoiler–Feeding–Leveling–Roll-forming–Punching–Hydraulic-cutting– Output table

|

Item |

Parameters |

|

Coil thickness (mm) |

Max 2 mm |

|

Speed (m/min) |

6-8 |

|

Transmission type |

Gearbox |

|

Roll stations |

18 |

|

Main power (Kw) |

11 |

|

Main shaft (mm) |

Ø76 |

|

Cutter material |

Cr12MOV |

|

Cutting accuracy |

±0.5mm |

|

Hydraulic station power (Kw) |

5.5 |

|

Control system |

PLC |

Reviews

There are no reviews yet.