-

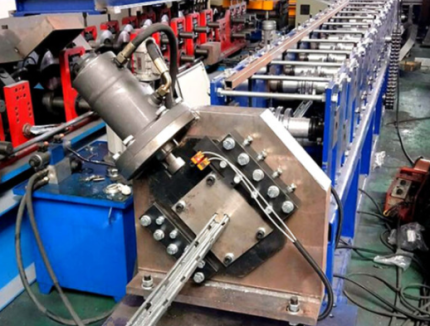

The Shutters Box Series Forming Machines than traditional equipment with high efficiency, low energy consumption, and reduce environmental pollution, the steel structure also has a considerable breakthrough, bring more benefits to the market, with galvanized steel or different color steel or aluminum plate as raw material pressure equipment production line rolling shutter door, product color plate production volume gate brilliant color, do not fade, do not rust, widely used in store, workshop, warehouse, fire partition, strength is higher than the aluminum alloy door.

-

Working Flow: Decoiler — Guiding device — Roll forming — Cutting device — Run out table

|

Suitable to process |

Color steel plate, galvanized sheet, aluminum coils |

|

Width of the feeding material |

914-1250mm |

|

Roller station |

11-18 rows or custom as customer’s requirements |

|

Thickness of feeding material |

0.3-0.8mm |

|

Productivity |

10-15 m/min |

|

Rollers’ material |

45# steel |

|

Diameter of shaft |

70-80mm |

|

Voltage |

380V 50Hz 3Phases |

|

Main forming machine body |

300-400 mm H steel |

|

Motor power |

4-7.5 kw |

|

Weight |

About 5-15T |

|

Custom |

According to customer’s requirements |

Reviews

There are no reviews yet.