Curbstone slipform molding machine can be used for on-site pouring and construction, and the entire curbstone laying process can be completed at one time, which can improve work efficiency and reduce labor intensity. Plastic concrete or dry hard concrete after being compacted is fashioned by the molds, continuously vibrating and tamping while the equipment move forward. The fashioned curb has high impact strength and stability, more advanced than the traditional ways.

It is widely used in highway curb construction. It can be produced on-site under various harsh working conditions, thereby eliminating the need for prefabrication renting and preparatory work, as well as material waste in the prefabrication process and loss in transportation and on-site installation. It can effectively overcome the construction difficulties caused by the tight road construction period and the narrow site. Up to now, it has been widely used in road construction in many provinces across the country, and has achieved good economic and social benefits.

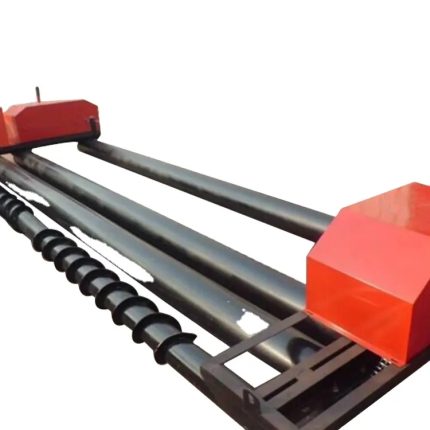

The machine is a special equipment for building road curbs, shoulders and intermediate isolation belts by using cement concrete. It is widely used in one-step molding of curbs of high-grade highways, county-level highways and municipal roads. Can be equipped with dry or wet molds and sensors according to curb construction requirements

Technical Data

| Item | Y automatic road kerb machine with kerb molds |

| Model | KB4 |

| Power System | 8.5KW single cylinder, water cooling diesel, electric start |

| Kerb Stone Molding Method | Plastic Concrete(high strength) |

| Dry Concrete(Compact Shape) | |

| Paving Way | 1-5m/min |

| Paving Size | 600*400mm |

| Bucket Volume | 0.3m³ |

| Weight | 1000kg |

| Dimension | 2500*1850*1100mm |

Reviews

There are no reviews yet.