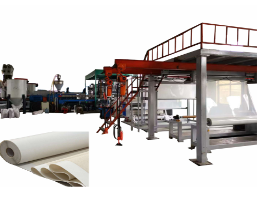

This production line is based on the previous multi-functional geomembrane production, adding a set of roughening device, which can meet the requirements for the production of roughening geomembrane.

At present, the production of rough surface geomembrane usually includes spinneret roughening method, nitrogen filling roughening method, and calendering method. The spinneret roughening method belongs to secondary molding, which is a method of preparing rough geomembrane by spraying molten plastic wire on the surface of the geomembrane to be roughened by special plastic spraying equipment. The advantages of this production method are as follows:

1. Compared with the nitrogen filling and roughening method, it will not form bubbles or holes on the surface or inside of the geomembrane, thus reducing the quality indicators of the geomembrane.

2. Compared with the embossing roller calendering method, the equipment investment is relatively small, the processing cycle is short, and the surface of the rough geomembrane produced by calendering method is uniform, flat, and the surface friction is relatively small. If the rough surface of different specifications is required, the embossing roller needs to be replaced constantly.

3. As the spinneret roughening method is the second roughening after the geomembrane production, the raw material requirements for geomembrane production are loose. And for manufacturers with film blowing equipment or calendering equipment, they can produce rough geomembrane without equipment modification.

4. The spinneret roughening method is suitable for producing rough geomembrane with different thickness.

At present, on the market, the process of spraying rough geomembrane is the most material saving and meeting the requirements of the index.

Reviews

There are no reviews yet.